by Ranger Kidwell-Ross, Editor of WorldSweeper.com and Executive Director of the World Sweeping Association.

by Ranger Kidwell-Ross, Editor of WorldSweeper.com and Executive Director of the World Sweeping Association.

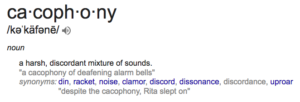

Can you say ‘cacophony?’ A good definition would be the sound when one enters the Roots horn factory, where there was a considerable din being made. Most of that was from the large size of the factory space, not the fact that horns were being produced in the facility. The size of the building was as impressive as the hustle and bustle taking place inside.

However, as I acclimated to what I was seeing it became clear that before me a well-choreographed ‘dance’ was taking place. Although no one appeared to be rushing, at the same time everyone moved with that quick efficiency borne from good training and experience. Ahh, I thought, so that’s what makes it possible to produce so many products in a year’s time!

There were dedicated assembly lines, as well as a variety of support personnel on the periphery doing a myriad of tasks. Seeing so many people in concerted motion gave me a sensation not unlike that of mild vertigo. I must say the view was inspiring.

Although horn-making doesn’t have anything much to do with power sweeping — even if the same company now makes a 6 cubic yard capacity regenerative air road sweeper — I thought my WorldSweeper audience would enjoy seeing the sights and sounds of this side trip for themselves. However, although the Roots management team were gracious enough to allow me to video the scene at the time, and those videos were then posted, subsequently we were asked to take down the video due to its showing of some potential proprietary information.

Although horn-making doesn’t have anything much to do with power sweeping — even if the same company now makes a 6 cubic yard capacity regenerative air road sweeper — I thought my WorldSweeper audience would enjoy seeing the sights and sounds of this side trip for themselves. However, although the Roots management team were gracious enough to allow me to video the scene at the time, and those videos were then posted, subsequently we were asked to take down the video due to its showing of some potential proprietary information.

The videos showed a well-designed, well-orchestrated assembly line, as one might expect with a venture that makes 6-to-7 million horns per year. Oh, by the way, I’d estimate that it was about 90-degrees F in the building, but this isn’t an overbearing temperature to those used to the heat.

The videos showed a well-designed, well-orchestrated assembly line, as one might expect with a venture that makes 6-to-7 million horns per year. Oh, by the way, I’d estimate that it was about 90-degrees F in the building, but this isn’t an overbearing temperature to those used to the heat.

Timing is everything on the assembly line in place at the Roots horn factory. All participants have sufficient time to do their part prior to the assembly line moving on to the next assembler. As someone who had never visited an automated assembly line of this nature before, I enjoyed it immensely. Sorry we had to take down the very entertaining videos showing the assembly line in action!

Timing is everything on the assembly line in place at the Roots horn factory. All participants have sufficient time to do their part prior to the assembly line moving on to the next assembler. As someone who had never visited an automated assembly line of this nature before, I enjoyed it immensely. Sorry we had to take down the very entertaining videos showing the assembly line in action!

That concludes our visit to Roots’ horn factory. Next stop will be the facility where the company makes its small sweepers, scrubbers and pressure washers, as well as the Rosmech R6 regenerative air street sweeper, which is currently being produced for export to the Australian marketplace.

Recent Comments